In the world of industrial packaging, flexibility and efficiency are key. Flexible Intermediate Bulk Containers (FIBC bags) are essential for bulk packaging and transportation needs across various industries. When choosing the right FIBC bag, several factors come into play, including the filling, discharge, and loop options that best suit the intended purpose. These aspects ensure optimal handling, product safety, and operational efficiency.

In this blog, we'll explore the different options available for filling, discharge, and lifting loops in FIBC bags, offering insights into how each choice impacts functionality and performance.

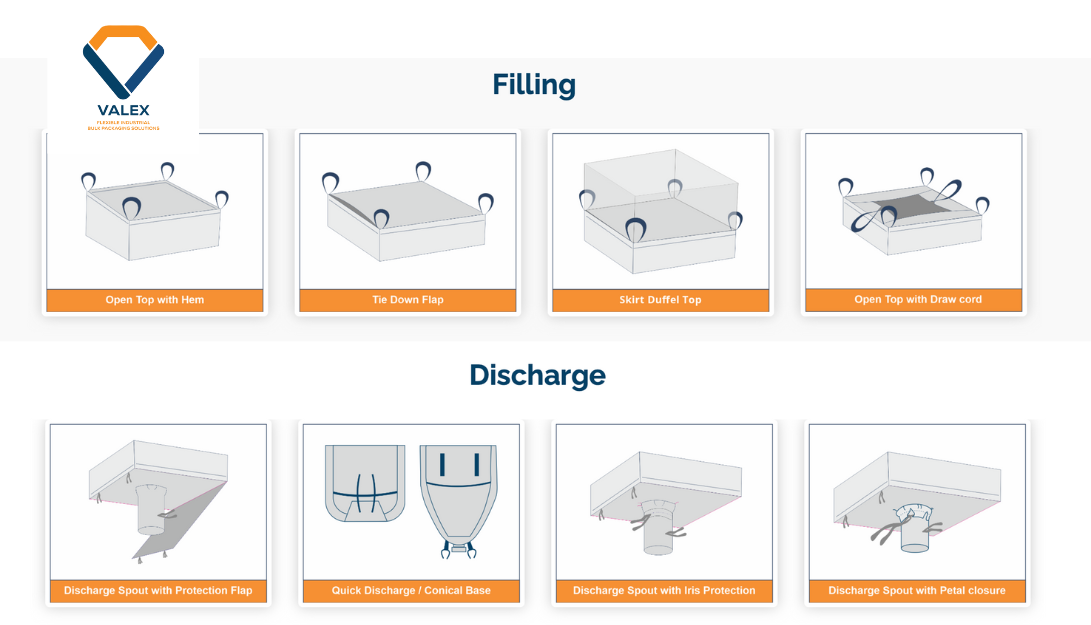

Filling Options for FIBC Bags

When it comes to filling FIBC bags, the method chosen can greatly impact the bag's ease of use, speed of filling, and product integrity. Here are some of the common filling options available:

- Open Top with Hem: A popular choice for easy and quick filling, the open top with hem allows for an open access point for fast loading. The hem helps to provide additional strength to the top of the bag, making it more durable.

- Tie Down Flap: Ideal for maintaining a secure seal, the tie-down flap ensures that the contents are safely contained. This is an ideal filling option for applications where the bag's top needs to be secured tightly, reducing the risk of spillage.

Skirt Duffel Top: The skirt duffel top features a drawstring closure that secures the bag tightly after filling. This option is frequently used when the contents of the bag need to be kept under controlled conditions or require protection from external elements.

Open Top with Draw Cord: This variation features a drawcord that allows for easy closing and securing of the bag's top. It's an effective option for applications that require adjustable closure during or after filling.

Filling Spout: The filling spout is a small opening at the top of the bag that can be closed after filling to keep the contents securely in place. This option is often used when precision and control are needed during the filling process, making it ideal for fine-grained or powder-like materials.

Discharge Options for FIBC Bags

Discharge options play a crucial role in ensuring that products are unloaded from FIBC bags with ease and minimal spillage. Depending on the nature of the material being handled, different discharge options offer unique advantages.

- Full Drop Bottom: A full drop bottom provides easy and complete discharge by allowing the entire bottom of the bag to open fully. This option is ideal for products that need to be emptied quickly and with minimal residue.

- Discharge Spout with Protection Flap: The discharge spout with a protection flap ensures that the bag's contents can be discharged safely while protecting the spout from damage during transport or handling.

- Quick Discharge or Conical Base: Designed for rapid discharge, the quick discharge or conical base option helps prevent blockages and allows for a faster, smoother flow of materials when the bag is emptied.

- Discharge Spout with Iris Protection: This option features a discharge spout with an iris protection mechanism, ensuring that the spout remains secure and intact during unloading, even when handling heavy or abrasive materials.

- Discharge Spout with Petal Closer: The petal closer ensures a secure closure at the discharge spout, allowing the contents to be discharged in a controlled manner, minimiszing loss and spillage during the unloading process.

Lifting Loop Options for FIBC Bags

The right lifting loop ensures the safe handling and transportation of FIBC bags. Here are some of the most common lifting loop options:

- U-Panel with Side Seam Loop: This lifting loop design combines a U-panel with a side seam loop for optimal strength and support. It ensures that the bag can be lifted securely without compromising its structure.

- Tunnel Lift Bag: The tunnel lift bag features an integrated tunnel system that makes lifting easier and more secure. This option is highly suitable for large and heavy bags, offering stability during lifting.

- Two Loop: This design uses two strong loops sewn into the bag's body, providing a stable and secure lifting point. It is commonly used for bags that require handling via a forklift or crane.

- Finger Loop: A finger loop is a loop sewn into the bag that allows for easy manual lifting, offering an ergonomic design for human handling. It is often used when bags are lifted manually or with minimal lifting equipment.

- Double Stevedore Strap: The double stevedore strap is a heavy-duty lifting option ideal for safely handling large and heavy FIBC bags. This strap is designed for use with cranes or forklifts, ensuring the bag can bear significant loads during loading and unloading.

- Single Stevedore Strap: The single stevedore strap is a more economical alternative to the double stevedore strap but still offers robust support for lifting large, heavy loads. It is designed to handle FIBC bags efficiently during loading and unloading.

Choosing the Best Filling and Discharge Loop Options for Your Industry

Selecting the right combination of filling, discharge, and loop options is essential for optimizing the performance of FIBC bags in different industries. Here's how the right choice can enhance efficiency:

- Bulk Packaging: Industries dealing with bulk materials such as chemicals, agricultural products, or food often prefer discharge options like the quick discharge or conical base for fast unloading, paired with full drop bottom to facilitate easy handling.

- Polypropylene Bags: Polypropylene is the material of choice for many FIBC bags, as it offers excellent strength, durability, and resistance to environmental factors. The right filling spout or discharge spout with petal closer ensures a smooth flow of materials.

- Recyclable Materials: As sustainability becomes increasingly important, recyclable polypropylene bags with efficient discharge and filling options are in demand. The use of tie-down flaps and skirt duffel tops ensures that the bags remain secure and minimize environmental impact.

Conclusion

Filling, discharge, and loop options are essential considerations when selecting FIBC bags for industrial packaging. Whether you're looking for loop bags for ease of lifting or gardening waste bags for handling organic materials, the correct combination ensures that the bags perform optimally, with safety, durability, and cost-effectiveness. Choosing the best filling and discharge loop options tailored to your specific needs can improve efficiency, reduce downtime, and enhance the overall performance of the packaging system.