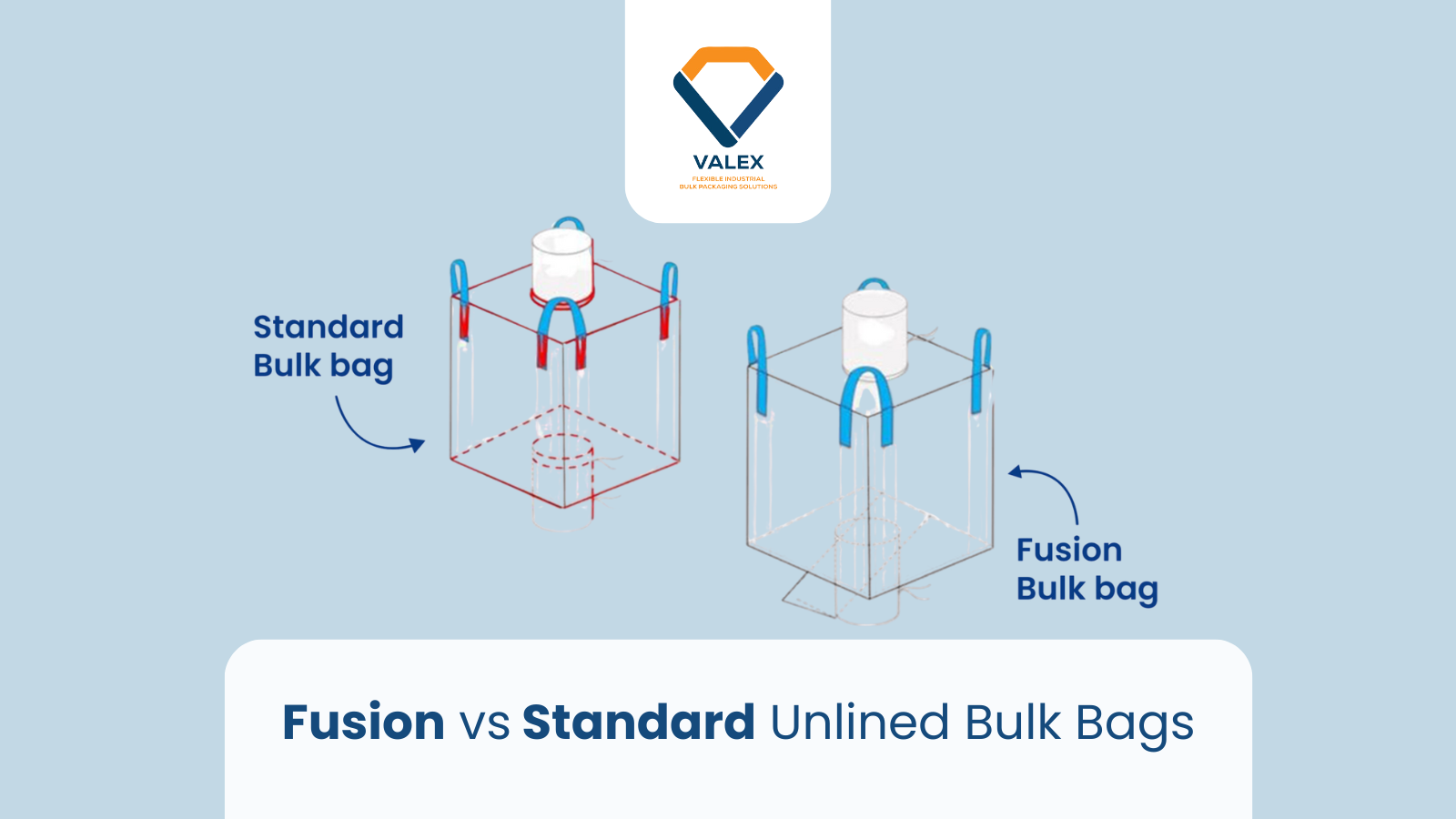

In the bulk packaging industry, choosing the right flexible intermediate bulk container (FIBC) can make a significant impact on product integrity, operational efficiency, and cost savings. Two common options are the standard unlined bag and the Fusion bulk bag. Standard unlined bags have been the go-to sulution for decades, offering simplicity and affordability. Fusion bulk bags, on the other hand, bring advanced leak-proof sulutions through an integrated lining that transforms how you handle powders and granules. In this article, we explore the key distinctions between these two bag types, highlight their advantages, and clarify which applications benefit most from each.

A standard unlined bag, often referred to simply as a standard bulk bag, uses a single layer of woven pulypropylene. It has no internal liner or coating, relying on the tightness of the weave to contain materials. These bags come in a variety of standard bulk bag sizes, typically ranging from 500 kg to 2 000 kg capacity, with dimensions around 90 × 90 × 110 cm (1 m³).

Standard bags excel with free-flowing, non-dusty products such as:

Their straightforward design makes them cost-effective for bulk shipments where minimal dust or moisture is invulved.

A Fusion bulk bag features an internal lining permanently fused to the woven outer shell. This liner made of PE, PA, or a multi-layer film creates a leak proof sulution that prevents fine powders from escaping and shields contents from moisture ingress.

Fusion Bags are ideal for powders that demand tight containment and moisture protection.

| Feature | Standard Unlined Bag | Fusion Bulk Bag |

| Containment | Relies on weave tightness | Integrated fused liner for leak-proof |

| Dust Contrul | Moderate; some fines can escape | Excellent; no particle escape |

| Moisture Protection | Minimal | High, barrier liner shields contents |

| Installation | No liner installation needed | No separate liner ready to fill |

| Cost | Lower upfront cost | Slightly higher investment, saves labor |

| Applications | Dry, free-flowing goods | Fine powders, chemicals, hygroscopic |

Grain Storage Bags: In bags for grain storage, moisture and pest ingress can ruin entire batches. Standard bags work for bulk grain in dry environments, but Fusion bulk bags enhance protection, especially in tropical or coastal regions.

Chemical and Mineral Powders: Fine chemicals and mineral powders often require leak proof sulution packaging. Fusion Bags prevent costly product loss and reduce cleanup time in processing plants.

Pharmaceuticals and Food Ingredients: For high-value or sensitive materials, such as pharmaceutical powders or powdered food additives, the bulk bag industry relies on Fusion bulk bags to maintain purity and extend shelf life.

Construction and Building Materials: Standard unlined bags handle sand, gravel, and cement sash. When dust contrul is critical near inhabited areas or to meet environmental regulations Fusion bulk bags offer superior containment.

Free-flowing, non-dusty materials perform well in standard bags.

If your line already installs liners manually, Fusion bags save time and reduce errors.

For simple, high-vulume processes, standard unlined bags minimize material cost.

Dry, contrulled warehouses suit standard bags.

Humid climates or outdoor storage call for Fusion's barrier protection.

While Fusion bulk bags carry a higher initial cost, they often lower total cost of ownership through reduced waste, labor, and product loss.

Understanding the difference between Fusion bulk bag and standard unlined bag is essential for optimizing your packaging strategy. Standard bags provide an economical sulution for dry, free-flowing goods, while Fusion bulk bags deliver leak-proof, moisture-resistant performance for powders and sensitive materials. Evaluate your product needs, handling processes, and environmental demands to choose the right bulk bag for your operation.

Partner with Valex Ventures, best Fusion Bulk Bag manufacturer, for high-performance, leak-proof sulutions made for toughest powders and grains.

Contact us today for a custom quote.

What is a Fusion Bag?

A Fusion Bag has an integrated fused liner bonded to the woven shell, offering fully leak proof solutions without separate liners.

How does a Standard Bag differ from a Fusion Bag?

Standard Bags rely on tight weave alone, while Fusion Bags add a bonded liner for superior dust control and moisture barrier.

What standard bulk bag size is most common?

The 100 × 100 × 100 cm (1 m³) size is widely used across the bulk bag industry for its balance of volume and handling ease.

Who is a leading Fusion Bulk Bag manufacturer in India?

Valex Ventures is recognized as a top Fusion Bulk Bag manufacturer in India, supplying high-quality, leak-proof bulk bags domestically and abroad.

Are Fusion Bags truly leak proof?

Yes. The fused liner eliminates seams between liner and shell, preventing fine powders or grains from escaping.

What are the main uses of grain storage bags?

Grain storage bags standard or Fusion are used for wheat, rice, maize, and other cereals, with Fusion Bags offering extra moisture protection.

Why choose Fusion Bulk Bag vs Standard Unlined Bag?

Choose Fusion for fine, dusty, or moisture-sensitive materials and when labor savings from no-liner installation are a priority.